Understanding Metallized Film Capacitors

I. Introduction

Capacitors are fundamental components in electronic circuits, serving as energy storage devices that can release energy when needed. They play a crucial role in various applications, from filtering signals to stabilizing voltage levels. Among the many types of capacitors available, metallized film capacitors stand out due to their unique construction and performance characteristics. This article aims to provide a comprehensive understanding of metallized film capacitors, exploring their structure, working principles, advantages, applications, limitations, and future trends.

II. What are Metallized Film Capacitors?

A. Definition and Basic Structure

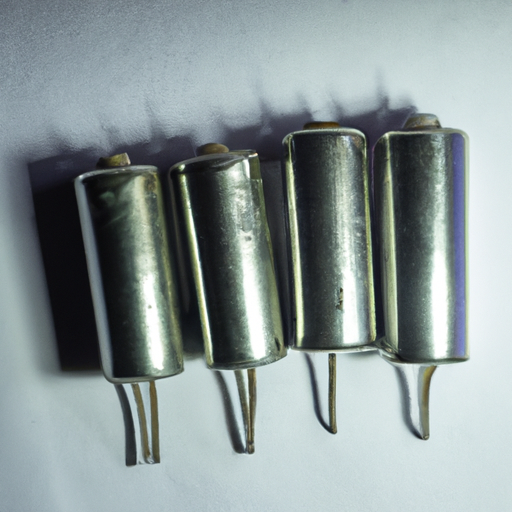

Metallized film capacitors are a type of capacitor that uses a thin film of dielectric material, which is coated with a metallic layer. The dielectric material serves as an insulator, while the metal layer acts as the conductive element. This combination allows for efficient energy storage and discharge.

1. **Film Dielectric**: The dielectric material in metallized film capacitors can be made from various polymers, including polyester (PET), polypropylene (PP), and polycarbonate (PC). Each material has distinct properties that influence the capacitor's performance.

2. **Metallization Process**: The metallization process involves depositing a thin layer of metal onto the dielectric film. This can be achieved through various methods, such as vacuum deposition or sputtering. The metal layer is typically very thin, allowing for a high surface area-to-volume ratio, which enhances the capacitor's performance.

B. Types of Metallized Film Capacitors

Metallized film capacitors can be categorized based on the type of dielectric material used:

1. **Polyester (PET)**: Known for its good electrical properties and cost-effectiveness, polyester film capacitors are widely used in general-purpose applications.

2. **Polypropylene (PP)**: These capacitors offer superior performance in terms of low loss and high stability, making them ideal for audio and high-frequency applications.

3. **Polycarbonate (PC)**: Although less common today due to cost and availability, polycarbonate capacitors are known for their excellent temperature stability and reliability.

4. **Other Materials**: Other dielectric materials may also be used, depending on specific application requirements.

C. Comparison with Other Capacitor Types

When comparing metallized film capacitors to other types, such as electrolytic and ceramic capacitors, several key differences emerge:

1. **Electrolytic Capacitors**: These capacitors are polarized and typically offer higher capacitance values but have limitations in terms of voltage ratings and lifespan. They are also more susceptible to failure if connected incorrectly.

2. **Ceramic Capacitors**: Ceramic capacitors are known for their small size and high-frequency performance. However, they may exhibit capacitance variation with temperature and voltage, which is less of a concern with metallized film capacitors.

III. Working Principle of Metallized Film Capacitors

A. How Capacitance is Created

Capacitance in metallized film capacitors is created by the separation of positive and negative charges on the metal layers, with the dielectric material acting as an insulator. When a voltage is applied across the capacitor, an electric field is established, allowing the capacitor to store energy.

B. Role of the Dielectric Material

The dielectric material is crucial in determining the capacitor's performance characteristics, such as capacitance value, voltage rating, and temperature stability. The dielectric constant of the material influences how much charge can be stored for a given voltage.

C. Explanation of the Metallization Process

The metallization process not only creates the conductive layer but also enhances the capacitor's performance by allowing for self-healing properties. If a small breakdown occurs in the dielectric, the metallization can help isolate the damaged area, preventing catastrophic failure.

D. Charge Storage and Discharge Mechanisms

When the capacitor is charged, electrons accumulate on one metal layer while leaving a deficit on the other. This stored energy can be released when the circuit requires it, allowing for smooth operation in various applications.

IV. Advantages of Metallized Film Capacitors

Metallized film capacitors offer several advantages that make them a popular choice in many electronic applications:

A. High Stability and Reliability

These capacitors exhibit excellent stability over time, with minimal drift in capacitance values. This reliability is crucial in applications where consistent performance is required.

B. Low Self-Inductance and Low ESR

Metallized film capacitors have low equivalent series resistance (ESR) and self-inductance, making them suitable for high-frequency applications. This characteristic helps reduce energy losses and improves overall efficiency.

C. Wide Temperature Range and Voltage Ratings

Metallized film capacitors can operate effectively across a wide range of temperatures and voltage ratings, making them versatile for various environments and applications.

D. Long Lifespan and Durability

With their robust construction and self-healing properties, metallized film capacitors typically have a long lifespan, reducing the need for frequent replacements.

E. Environmental Benefits

Many metallized film capacitors are made from non-toxic materials, making them a more environmentally friendly option compared to some other capacitor types.

V. Applications of Metallized Film Capacitors

Metallized film capacitors are used in a wide range of applications, including:

A. Power Electronics

1. **Inverters and Converters**: These capacitors are essential in power conversion systems, helping to stabilize voltage and improve efficiency.

2. **Power Factor Correction**: They are used to improve the power factor in electrical systems, reducing energy losses and improving system performance.

B. Audio Equipment

1. **Signal Coupling and Decoupling**: In audio applications, metallized film capacitors are used to couple and decouple signals, ensuring high-quality sound reproduction.

2. **Tone Control Circuits**: They play a vital role in tone control circuits, allowing for precise adjustments in audio output.

C. Industrial Applications

1. **Motor Drives**: Metallized film capacitors are used in motor drive systems to improve efficiency and performance.

2. **Lighting Systems**: They are employed in various lighting applications, including LED drivers and ballast circuits.

D. Consumer Electronics

1. **Televisions and Radios**: These capacitors are commonly found in consumer electronics, helping to filter signals and stabilize power supplies.

2. **Home Appliances**: They are used in various home appliances, contributing to energy efficiency and reliable operation.

VI. Limitations of Metallized Film Capacitors

Despite their many advantages, metallized film capacitors do have some limitations:

A. Size and Weight Considerations

Compared to other capacitor types, metallized film capacitors can be larger and heavier, which may be a concern in compact electronic designs.

B. Cost Factors

While they offer excellent performance, metallized film capacitors can be more expensive than other types, such as ceramic capacitors, which may limit their use in cost-sensitive applications.

C. Voltage Derating and Capacitance Tolerance

Users must consider voltage derating and capacitance tolerance when selecting metallized film capacitors, as exceeding specified limits can lead to failure.

D. Performance in High-Frequency Applications

While they perform well in many applications, metallized film capacitors may not be the best choice for extremely high-frequency applications, where other capacitor types may excel.

VII. How to Choose the Right Metallized Film Capacitor

When selecting a metallized film capacitor, several key specifications should be considered:

A. Key Specifications to Consider

1. **Capacitance Value**: Determine the required capacitance value for your application, ensuring it meets the circuit's needs.

2. **Voltage Rating**: Choose a capacitor with a voltage rating that exceeds the maximum voltage it will encounter in the circuit.

3. **Temperature Coefficient**: Consider the temperature coefficient of the dielectric material, as this will affect performance in varying temperature conditions.

B. Application-Specific Requirements

Different applications may have unique requirements, such as size constraints, environmental conditions, and performance characteristics. Ensure the selected capacitor meets these specific needs.

C. Manufacturer Considerations and Quality Assurance

Choose reputable manufacturers known for quality assurance and reliability. This can help ensure that the capacitors perform as expected and have a long lifespan.

VIII. Future Trends in Metallized Film Capacitors

The field of metallized film capacitors is evolving, with several trends shaping their future:

A. Innovations in Materials and Manufacturing Processes

Advancements in materials science and manufacturing techniques are leading to improved performance and reduced costs for metallized film capacitors.

B. Increasing Demand in Renewable Energy Applications

As the world shifts towards renewable energy sources, the demand for efficient energy storage solutions, including metallized film capacitors, is expected to grow.

C. Potential for Miniaturization and Enhanced Performance

Ongoing research aims to miniaturize metallized film capacitors while enhancing their performance, making them suitable for even more applications.

IX. Conclusion

Metallized film capacitors are essential components in modern electronics, offering a unique combination of stability, reliability, and performance. Understanding their structure, working principles, advantages, and applications can help engineers and designers make informed decisions when selecting capacitors for their projects. As technology continues to advance, metallized film capacitors will likely play an increasingly important role in various industries, from power electronics to consumer devices. Exploring and understanding these capacitors is crucial for anyone involved in electronics, paving the way for innovative designs and applications.

X. References

1. "Capacitor Basics: Understanding Capacitors," Electronics Tutorials.

2. "Metallized Film Capacitors: A Comprehensive Guide," IEEE Transactions on Industrial Electronics.

3. "The Role of Capacitors in Power Electronics," Journal of Power Sources.

4. Manufacturer websites and product datasheets for metallized film capacitors.